my mom was a proof reader at Webb Publishing in St. Paul, Minnesota… in February 1968, my older brother was killed in action in Vietnam… he was just a year and a half older than me and we were very close… I remember answering the door at my parents house and seeing the army officer and the minister standing there… it was horrible and sent me into what I now realize must have been a pretty deep depression… I would sleep 20 hours and then sometimes, instead of waking, I would go into what I called a “catatonic” state where I was awake and alert but my whole body was paralyzed and could not move… my visual field was a like the screen of an old fashioned color tv with jagged lines of color moving across it and my brain seemed to be sizzling like a frying pan… these spells were terrifying… I was trying to attend the University of Minnesota as an art major, English minor, but I could not concentrate on my school work… I would try and force myself to read and the pages of text would blur before my eyes… I was basically at war with the faculty of the University Art Department (all abstract expressionists from New York – while I was trying to paint like Caspar David Friedrich)… I was kind of a wreck…

in the summer of 1968, I needed a job and my mom told me they were hiring in the pressroom of the publishing company where she worked, Webbs… so I went and applied… it was a union job so, I could only work three months as a temp before I had to either quit or join the union… so, I worked there off and on for the next four years, sometimes for a few weeks, sometimes a bit longer, earning enough to keep me in school… I was struggling with my classes… but worked at Webbs during school holidays and sometimes even while school was in session… whenever I worked it was night shifts, either 3 pm to 11 pm or 11 pm to 7 am…

I had my first taste of the real factory world when I first walked into the pressroom… it was a huge open building filled with giant printing presses… the noise was incredible… the presses roared and pounded… the huge rotating drums of the presses were lubricated with what was called an oil mist… this mist would get hot and smoke… so all of he hot bearings were smoking into the air… also, there was a constant mist of ink from the huge ink rollers, which rotated at tremendous speed and sprayed a fine mist of oil based ink into the air… there was a ventilation system but the air was always thick with oil smoke, ink and paper dust…

there were two kinds of printing presses, letterpresses and offset presses… I worked mostly on the letterpresses… when I started, there were two letterpresses and several offset presses… the letterpresses were situated next to each other… the one I worked on most was called The Telephone Press… The Telephone Press was yellow while the offset presses were green… it was used exclusively for printing telephone books… the press consisted of three parts… at the back was the reel stand… this was a steel structure about 15 feet tall… there was an axle, maybe a foot thick and this axle had three arms sticking out on each side to hold the rolls of paper… each roll of paper weighed approximately 1 ton… the rolls were about 4 feet in diameter and 6 feet long… when the reel stand was full, the three rolls could be rotated… there were belts above the top roll that would spin the roll at a very high rate of speed… the web of paper (called “the web”) came off the roll, went through some steel rollers of maybe six inches in diameter and then was fed into the printing unit through other steel rollers…

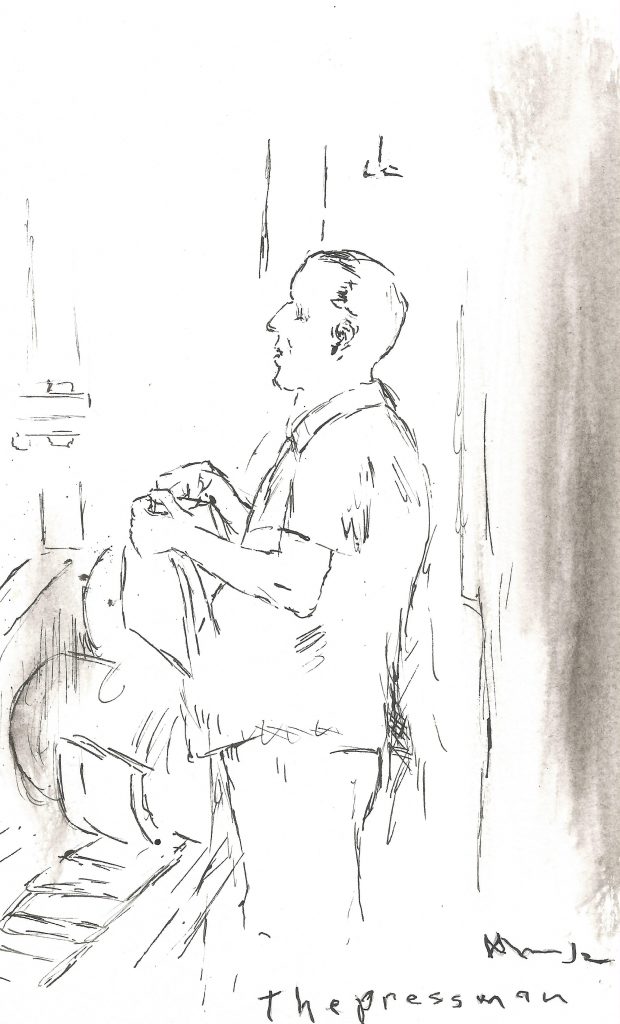

the printing unit consisted of two large drums, maybe a foot and a half in diameter and six feet long… one of these cylinders had the printing plates with raised type and the other had “blankets” of heavy coated cardboard and rubber… under the printing drum was an array of rubber ink rollers of various diameters that would pick up ink from a trough and spread it out so it would go evenly on the printing plates… the web would go between the printing plates and the blanket drum and be printed with the pages of the telephone book… because it operated with a web of paper and the plates printed directly on the paper, this was called a web fed letterpress…

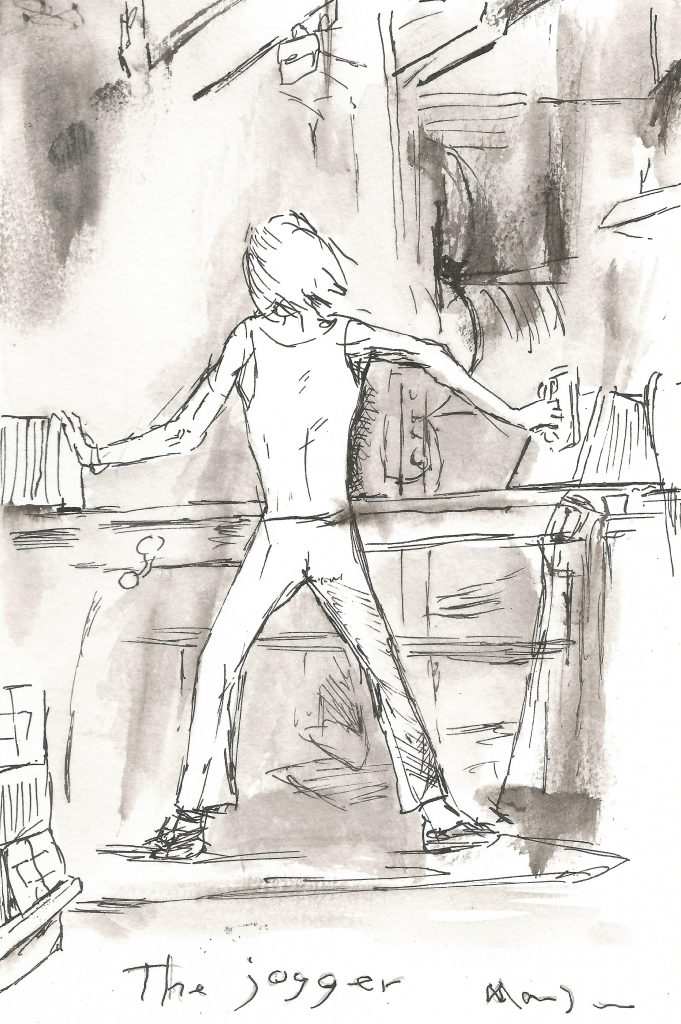

from the printing cylinders, the web was fed through other large rollers about three stories up where it entered the folder… there was a roller at the entrance of the folder which had sharpened discs that would slice the web into six smaller webs called “ribbons”… the ribbons then went around a maze of rollers and were fed down into the actual folder cylinders which were two large drums that would crash together with a sharpened “knife” that would cut the paper into pieces about the size of two pages of a telephone book but six pages thick… and a gripper on the cylinder would then fold the cut piece onto another cylinder which would lay it on a belt… what came on the belt was called a “signature”… the folder slammed the two steel cylinders together with a huge bang bang bang noise that became a constant roar as the press was brought up to speed… the signatures were fed onto a table where the least senior person on the press crew, “the jogger,” would stand… the signatures would be stood up on this table by a belt with another belt moving them forward… a board the size of a telephone book page would be at the front of this moving cube of signatures and a maybe ten pound weight with a handle like a coffee mug, would keep the signatures from sprawling onto the table or the floor…

the person handling the signatures as they moved along the table was the jogger… as the signatures or “books” as they were also called, moved along the table, the jogger would divide the books about three feet from the end to make a bundle, stick in a new bundle board and push that three foot bundle about three feet to the end of the table… he would then quickly move the heavy weight back to the new bundle board while holding the other bundle up and operating a foot peddle lever that brought two hydraulic teeth up through holes in the table, then a handle that moved the teeth, compressing the three foot bundle into a two and a half foot bundle… there was a space under the bundle where a wire with a prepared loop on one end would have been place after removing the last bundle… the jogger would then wrap this wire around the bundle, run the wire through the loop and wrap it around itself to secure the bundle… then reverse the levers to put the teeth back down to make room for the next bundle to be pushed down the table… the jogger would then pick up the bundle… the bundle was like two and half feet of telephone books, so pretty heavy, and stack it on a pallet… these would be stacked six layers high, so the jogger had to heave the bundle up for the top layers to make a neat stack…

as soon as the jogger finished one bundle, another would be ready… so the work was fast and heavy… two men would be assigned to the crew as joggers and they would take turns bundling, half hour on half hour off… some of the joggers were big strong guys who could throw the bundles up easily, even at the end of a shift… others, like me, had to have a technique… I would hoist the bundle up to shoulder height and then flip it up on the top of the stack… I especially remember two joggers I worked with… one was a huge guy with a British accent who said he learned how to kill people with his bare hands in the British army… he worked days as an adjunct at the University and said that he would offer female students good grades in exchange for sex… he said that after they had sex with him, he would give them bad grades anyway… I don’t know if any of that was true or not… I know that sometimes in the middle of a midnight shift, when he was off, his wife would call the pressroom and say he told her he was working that night… he one time gave us a demonstration, breaking a bundle board with a karate chop… while he was a lot of fun and full of bullshit stories, he was kind of lazy and it was hard to get him to do his share of the work… but man, I remember him tossing the bundles around like they were Kleenex boxes at the end of a long shift when my ass was dragging and I had all I could do to lift one more bundle… another jogger I remember was a very preppy looking guy who was working three jobs and would fall asleep on his break so nobody could find him when it was his turn to bundle… one annoyed coworker slipped some speed into his coffee one night… I remember seeing this usually very slow and sleepy guy doing jumping jacks between bundles that night… so I asked what that was about and the other jogger told me… when this guy found out, instead of being mad, he was delighted and started buying speed from one of the pressroom drug guys… I guess he liked burning the candle at both ends…

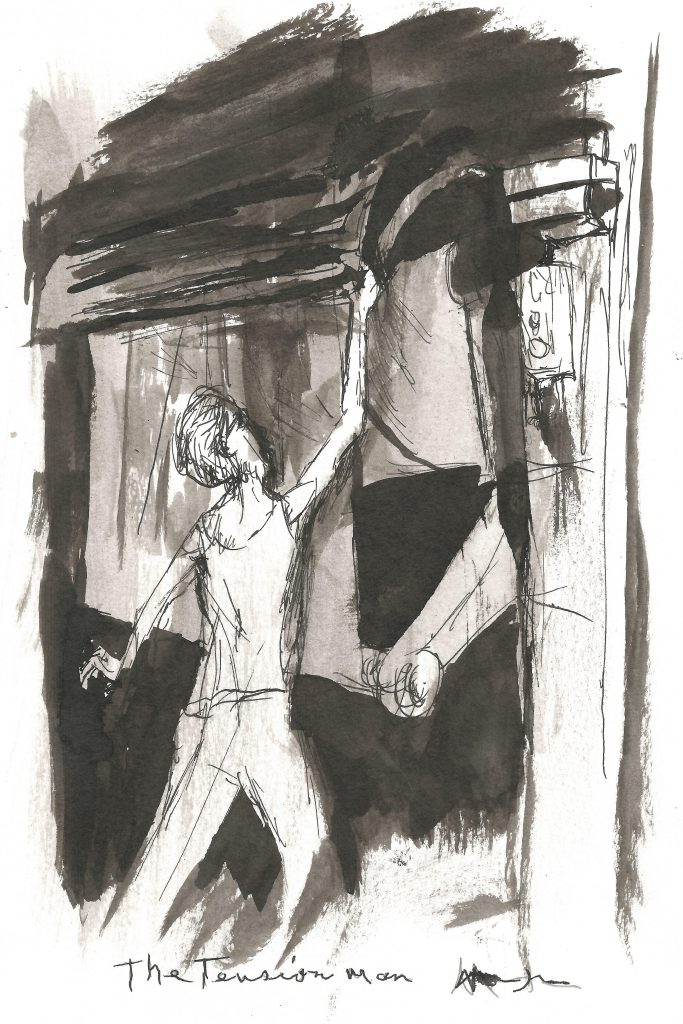

in addition to the two joggers, there would also be one pressman, usually an older guy, and his assistant who was called the “oiler” and in the back, the person who put the rolls on the press and spliced the old rolls onto the new rolls who was called the “tension man” because he was responsible for the tension of the web… when the rolls were almost wound down, the tension man would operate a lever that rotated the rolls so the old roll, which was now only like six inches in diameter, was at about waist height and the new roll was above it almost but not quite touching the web… the tension man would have prepared a “pattern” on the new roll which involved tearing the paper on the roll into a vee shape and then pasting glue with a brush onto the middle and outside of the vee pattern leaving a space for the belts… the paper was white or yellow and the glue was orange… the pattern was held to the roll with tape that was moistened with water and was called “gum stock”… the gum stock came from a small dispenser that the tension man would operate to get short strips of gum stock and stick those on the pattern in a certain way so the pattern could pull away without tearing the paper…

once the tension man had rotated the rolls so the spindle that was running out of paper was at waist height and the new roll was almost touching it, he would manually reach up and start the new roll spinning… then he would slowly lower the belts onto the new roll that would get it spinning the same speed as the web, which was pretty fast… the tension man would then lower a device into place that had a six foot long brush that he could operate to push the web of paper against the pattern on the new roll so the glue would grab onto the web and the paper would start coming off the new roll and then a six foot long knife would snap out and cut the old web which would flutter to the floor… the tension man would then unwind any waste paper from the steel core that the roll was wrapped on, remove the core and hang a new roll, put on a new pattern and get ready for the next roll change… the roll change was called a “paster”… and the tension man was responsible for “making the paster” which meant that the press kept running at speed from one roll to the next… if the tension man screwed up, he “blew the paster”… the press was equipped with devices that would slam brakes on all of the huge steel cylinders if the web broke and the whole roaring machine would crash to a stop… and the pressman would at the very least, give the tension man a dirty look… I got a lot of those looks during the ten years or so I worked as a tension man…

when the web broke, the whole crew had to scramble up onto the press to feed the web through the rollers, through the printing units and into the folder… if part of the web was still left, it could be patched with gum stock and so every person on the crew carried a sharp pocket knife to cut the web if need be… I remember on guy who had a tattoo that said, “I was born to lose but I am out to win” who would cut the web with a shiny black handled switch blade… once the press was “webbed up”, the joggers often got a break while the pressman would make minor adjustments to the printing plates or other parts of the machine… there was a button that would start the press moving and every time you pushed the button a loud bell rang before the press started moving… one had to be very careful around the press whenever it was moving because, of course, getting a finger in the printing cylinders or the folder would be the end of the finger and if the press was going fast, the end of the arm and probably the end of the worker…

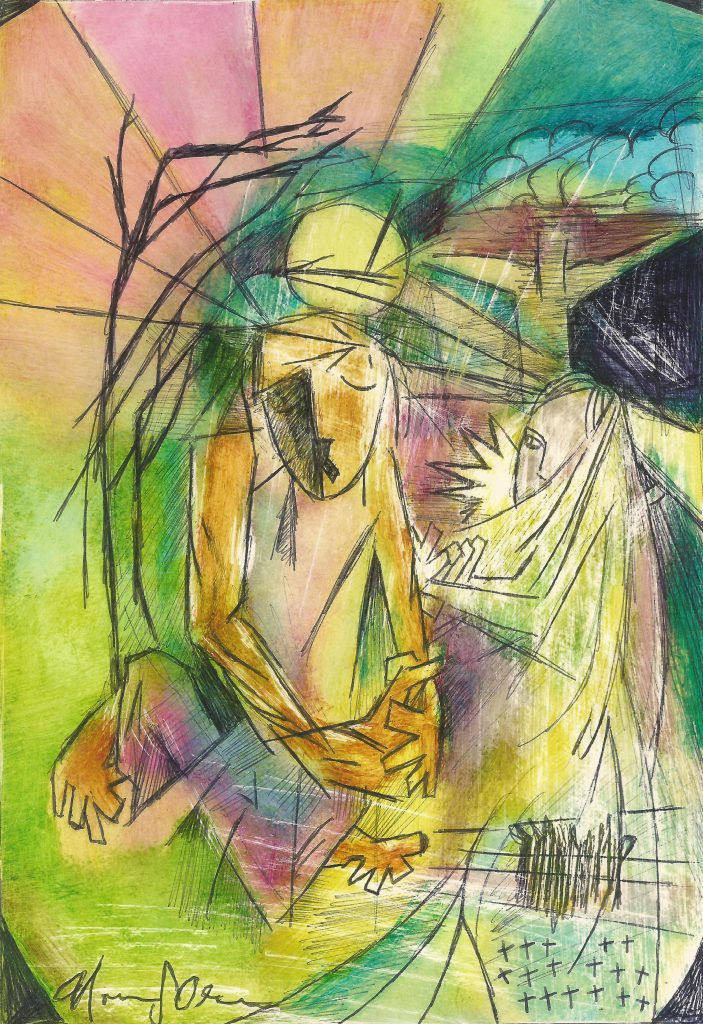

I worked off and on as a jogger from 1968 until 1972 when I decided to join the union and work full time at Webbs… after about five years as a jogger, I was promoted to tension man… I was very fast as a tension man (although I maybe blew a few too many pasters) and could get my rolls changed and patterns made in about ten minutes and it would take about a half hour for a roll to wind down, so I would get twenty minutes of free time for each roll… I spent that time doing school work (by the early 1970s, I was in grad school as an English major), reading novels and drawing… there was a stairway back in the corner behind the telephone press, a steel stairway that went up into some space that was never used as far as I knew… under the stairway, I had a five gallon ink can with a bundle of shop rages for a chair and I would sit there and either do my school work, read or draw while my rolls wound down… to my co-workers, I was the weird college guy, or the guy that made the “off the wall” drawings… other workers used their time between rolls to talk or eat… some read porno magazines (until the mid 1970s when a few women came to work in the pressroom) and more than a few would go out back into the “roll room” where the rolls of paper were stacked up to the ceiling or out on “the patio” which was the loading dock where freight cars full of paper were unloaded… to smoke a joint…

smoking cigarettes was allowed in the pressroom and we all smoked through the whole shift… the air was so thick with oil smoke and ink mist that I guess we mostly figured that the cigarettes would not make much difference… early on in my years at Webbs, I asked the supervisor for hearing protection… which I learned was available even though nobody used it at that time… by the time I left, it was mandatory and everybody used it, but many of the older guys were pretty deaf from the constant roar of the machines… by the time I left, the old Telephone Press had been moved and doubled in size… many new presses had been added and the company had gone from a small, highly profitable family business to a small cog in a global publishing empire… to out of business about ten years after I left…

so, I learned to draw, not in my art classes, which had been pretty much a waste of time, but sitting on an ink can in the corner of a dirty dusty pressroom drawing with a ballpoint pen on telephone book cover stock… which may account for some of the weirdness of my art… I used to make up poetry while I was setting up my rolls and then write it down when I had a few free minutes… all of those years, I worked nights… at first, I was driving to River Falls every afternoon to attend grad school classes and then working from 11 pm to 7 am printing telephone books… not getting much sleep… I dropped out of grad school in 1976 but continued reading, writing and making art… I left Webbs to take a civil service job in 1988… by then the presses had become more modern, bigger and faster and with smaller crews, so nobody got the kind of breaks that I had enjoyed on the old Telephone Press… now, I am an old man, few even remember what a telephone book was, and I could probably not even life a bundle of telephone book signatures, much less wrestle a 2000 pound roll of paper onto the spindles of a reel stand… some would say that working at that job all those years, I really pissed my life down a rat-hole… well maybe so… all I know is that for better or worse, I learned everything I know about making art sitting on an ink can, breathing paper dust, ink and oil smoke behind a huge yellow Wood-Hoe Telephone Directory Letterpress as night outside those dirty, ink stained walls turned to dawn…

Pingback: Synchronized Chaos November 2020: Zoomed Out | SYNCHRONIZED CHAOS